Recently, the Lithium/Sodium Battery Materials and Safety Technology Team of the School of Materials Science and Engineering of the University has made new progress in the research field of silicon-based anode for high-performance lithium-ion batteries, and the relevant research results are summarized in the following article: "In-Situ Artificial Hybrid SEI Layer Enabled High Performance Prelithiated SiOxAnode for Lithium-Ion Batteries" was published in the internationally recognized journal Advanced Functional Materials (Adv. Funct. Mater., 2023, 202303020.).

TheSilicon oxide (SiOx) is a strong candidate as a high-capacity anode material for next-generation lithium-ion batteries because of its advantages of high theoretical specific capacity, suitable working potential, and low cost. Compared with pure silicon materials, the volume change of SiOx during long-term cycling can be buffered by silicates and lithium oxides formed during the initial lithiation process. However, these irreversible buffering substances also deplete the active Li+ in the cell, leading to a decrease in the initial coulombic efficiency (ICE). The lithium loss in the initial cycle can be effectively compensated by the pre-lithiation strategy, which can substantially improve the ICE. however, with the deepening of pre-lithiation, the lithium-silicon alloy (LixSi) generated in SiOx poses a great challenge to the stability of the electrode interface and electrode structure, which affects the cycle life of the battery.

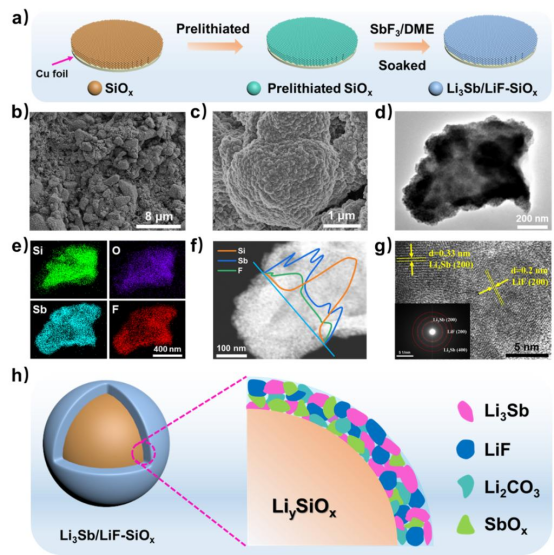

In this study, the Li3Sb/LiF artificial SEI interfacial layer was constructed in situ on the surface by regulating the pre-lithiation depth of the SiOx electrode and utilizing the electrode's own reducibility, which effectively suppressed the volume change of the SiOx particles in the charging and discharging process and homogenized the stress distribution to avoid the particle fragmentation and the collapse of the electrode structure. Meanwhile, based on theoretical calculations and experimental results, the interfacial layer is shown to have a lower Li-ion diffusion energy barrier, which can enhance the diffusion kinetics of Li+ at the electrode/electrolyte interface. The interface-optimized modified SiOx anode half-cell ICE is as high as 94.5%, and its capacity retention rate is still 77.4% after 200 cycles at 0.5 C. The SiOx anode has a higher capacity than that of the high-capacity NCM811 electrode, which has a higher capacity than that of the NCM811 electrode. Its full-cell ICE assembled with a high-capacity NCM811 positive electrode reached 86.0%, and it achieved 86.6% capacity retention after 100 cycles of 0.5 C cycling. This work provides new ideas and methods for rationally designing the structure and surface properties of SiOx to realize high-energy and long-cycle lithium-ion batteries.

This work was supported by the National Natural Science Foundation of China, the Anhui Outstanding Youth Science Foundation, the Anhui Major Special Project and the Anhui Key Research and Development Program, etc. Lecturer Yi Sun is the first author, master's student Kuanxin Zhang is the second author, Professor Hongfa Xiang is the corresponding author, and the Hefei University of Technology is the sole correspondent.

SiOx anode modified by Li3Sb/LiF artificial SEI interfacial layer

In recent years, the lithium/sodium battery materials and safety technology team led by Prof. Hongfa Xiang has made a series of progress in the direction of research and development of key technologies of high-performance electrode materials. Small", "Journal of Materials Science & Technology", "Journal of Power Sources" and "Chemical Communications" and other materials and energy journals, in the field of academic research for the University of Materials Physics and new energy materials and devices to provide strong support for the construction and development of the profession.

Link to the paper: https://onlinelibrary.wiley.com/doi/10.1002/adfm.202303020

(Sun Yi Xiang Hongfa/writing Zhang Kuanxin/figure Luo Laima/auditing)

Editor: Zhou Hui